Woamy’s cellulose foam protects against impacts

Recently published article in Maaseudun Tulevaisuus is exploring the Woamy’s foam potential.

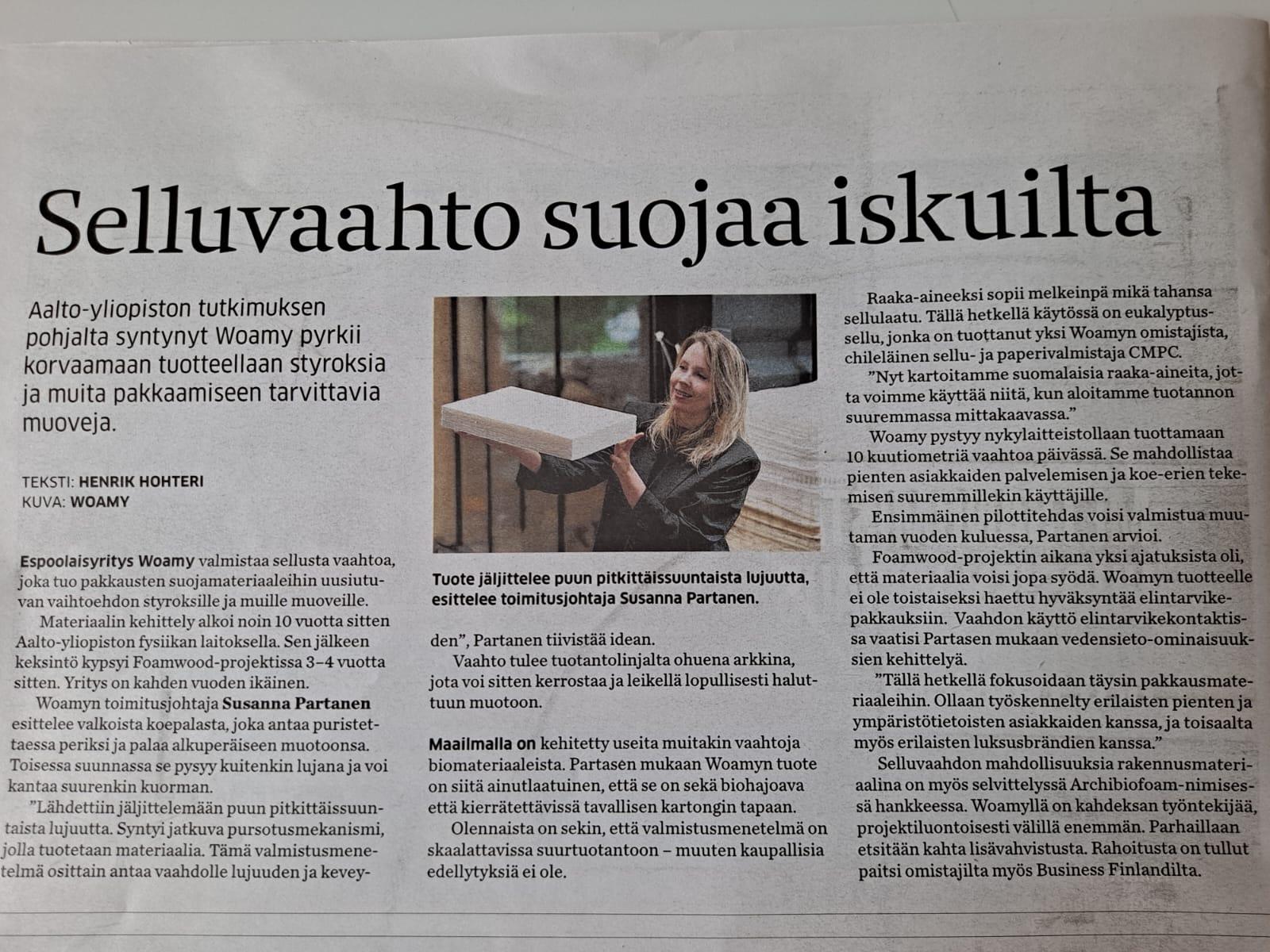

Based on research from Aalto University, Woamy is striving to replace styrofoam and other plastic materials used in packaging with its innovative product.

Espoo-based company Woamy produces cellulose foam, a sustainable alternative for packaging protective materials traditionally made of styrofoam and other plastics. The development of the material began around 10 years ago in Aalto University’s physics department. Following this, the company refined the technology through project called Foamwood over the past 3-4 years, aiming to commercialize the solution. “We aimed to mimic the long-fiber structure of wood, using a sustainable material. The product provides continuous strength, yet remains lightweight,” Partanen explains. The raw material used can be almost any type of cellulose. Currently, Woamy utilizes eucalyptus pulp supplied by one of its owners, the Chilean pulp and paper company CMPC.

“We are now exploring Finnish raw materials to scale up production further,” says Partanen. Woamy’s existing production line can generate up to 10 cubic meters of foam per day, allowing the company to cater to small-scale orders and pilot projects before moving to larger-scale production. The first commercial batches will be available within the year, according to Partanen. The Foamwood project, a significant milestone for the company, received a favorable evaluation for its sustainable packaging application. The product’s water-resistant properties also open new possibilities for diverse uses in packaging. “Here, our focus has been entirely on packaging materials. We have engaged extensively with environmental and packaging experts to tailor the solution for various customer needs,” Partanen adds.

Cellulose foam as a sustainable building material is also being investigated through the Archibiofoam project. Currently, Woamy has eight employees, with plans for expansion and further development of the foam technology.